A specialized manufacturer of automotive filter elements

ENVIORONMANTALLY FRIENDLY

FOR PEOPLE AND PLANET

FOR PEOPLE AND PLANET

OUR STRENGTH

Company

Main Clients

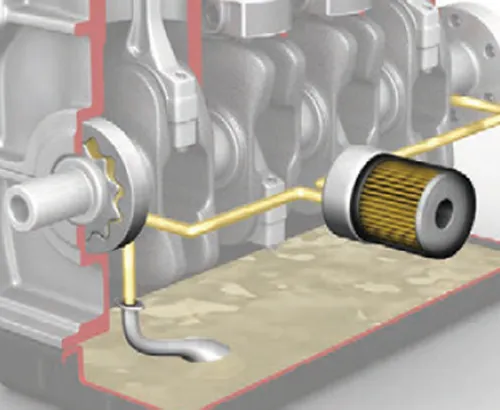

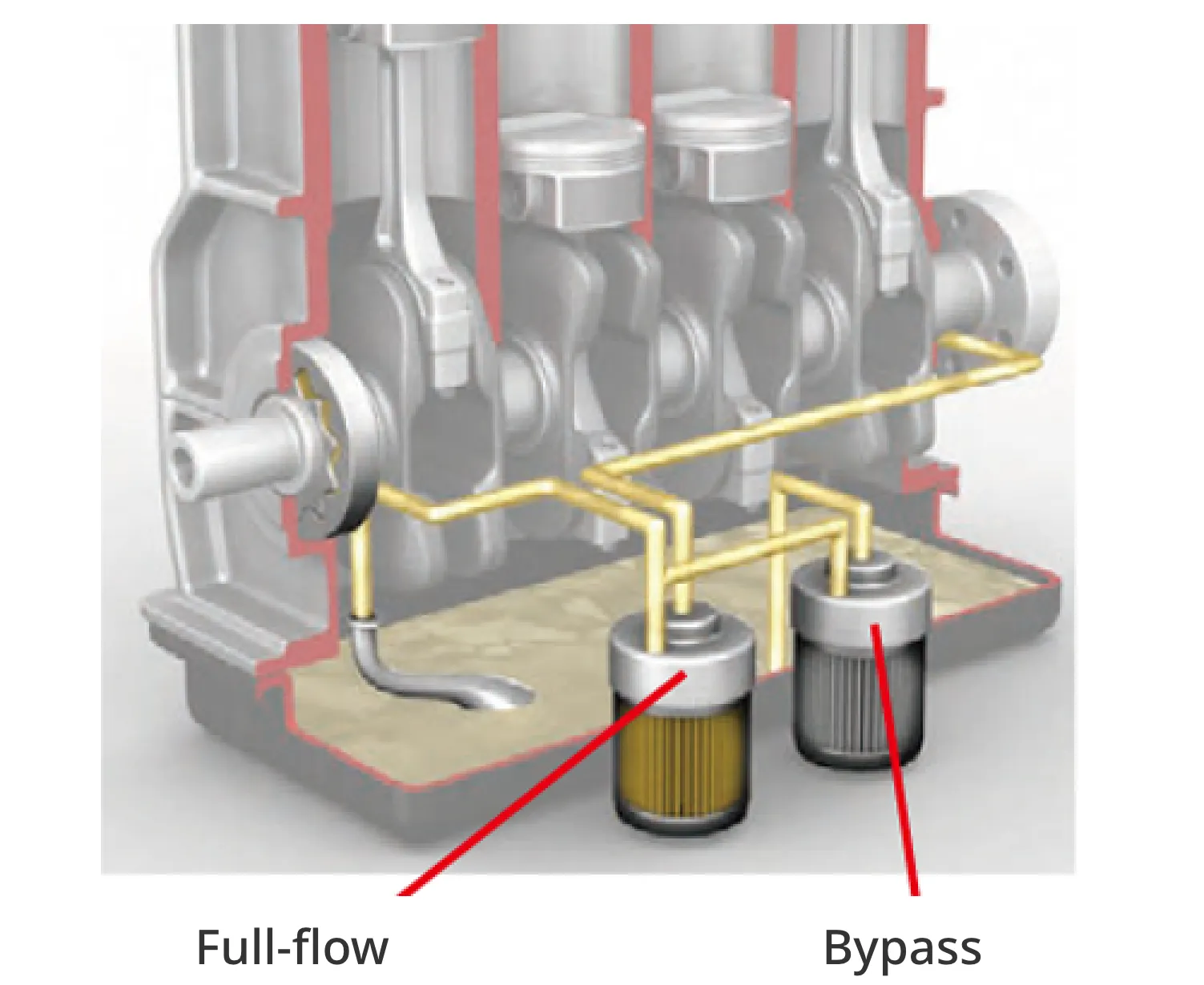

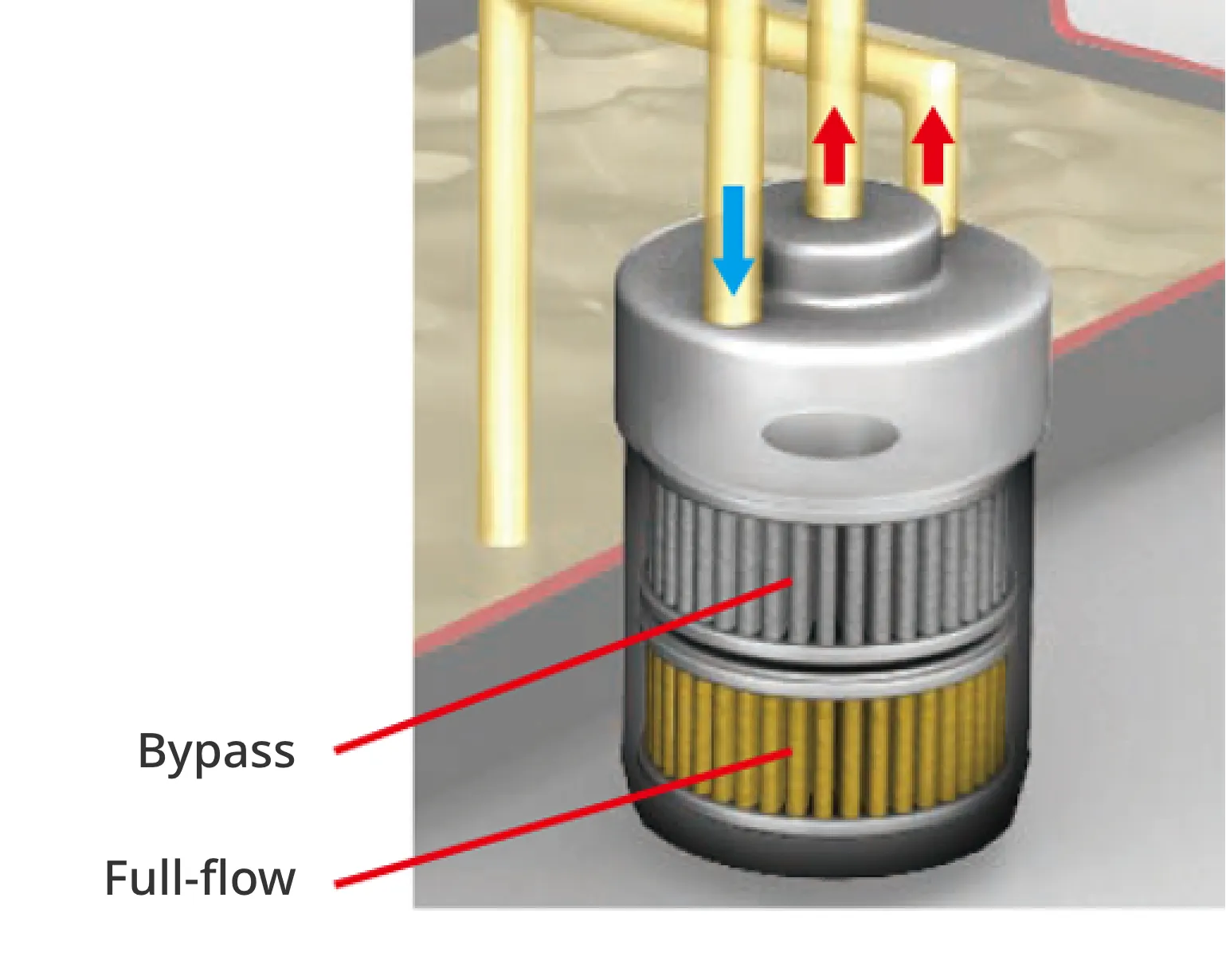

Oil filter

Remove impurities from circulating oil inside the engine.

Product Introduction

Image from : Japan Filter Element Manufacturers Association

Image from : Japan Filter Element Manufacturers Association

Image from : Japan Filter Element Manufacturers Association

Oil filter

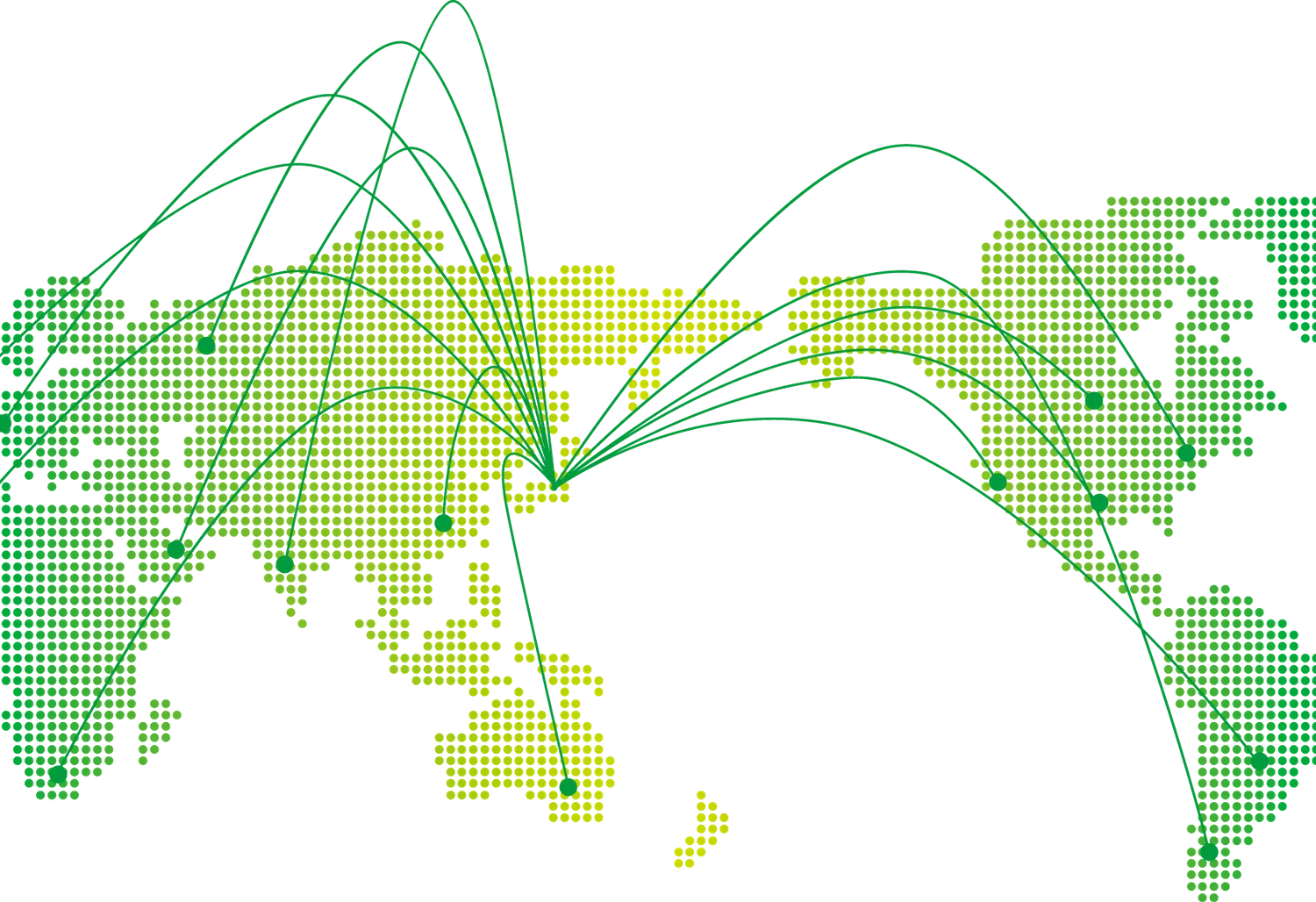

AIR FILTER

Filter cleans air from the impurities to maximize engine performance.

Product Introduction

AIR FILTER

FUEL FILTER

Product Introduction

Excellent Aluminum cold forging

High-precision filter paper used

Fuel Filter

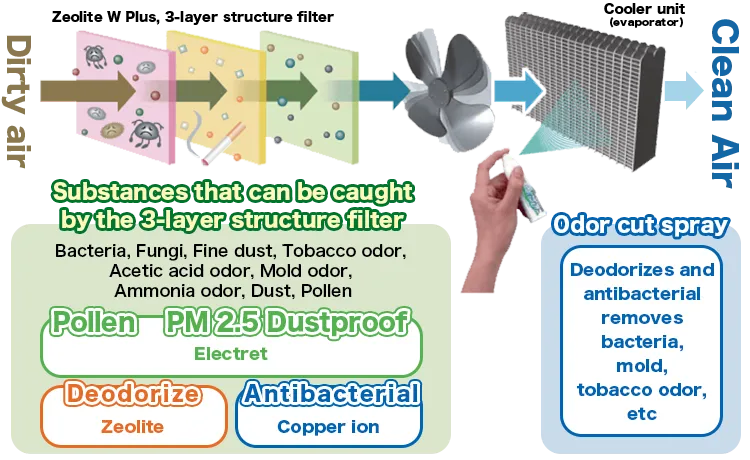

Cabin Filter

Air Conditioner filter for Vehicle

MICRO Air Conditioner filter makes your car comfortable

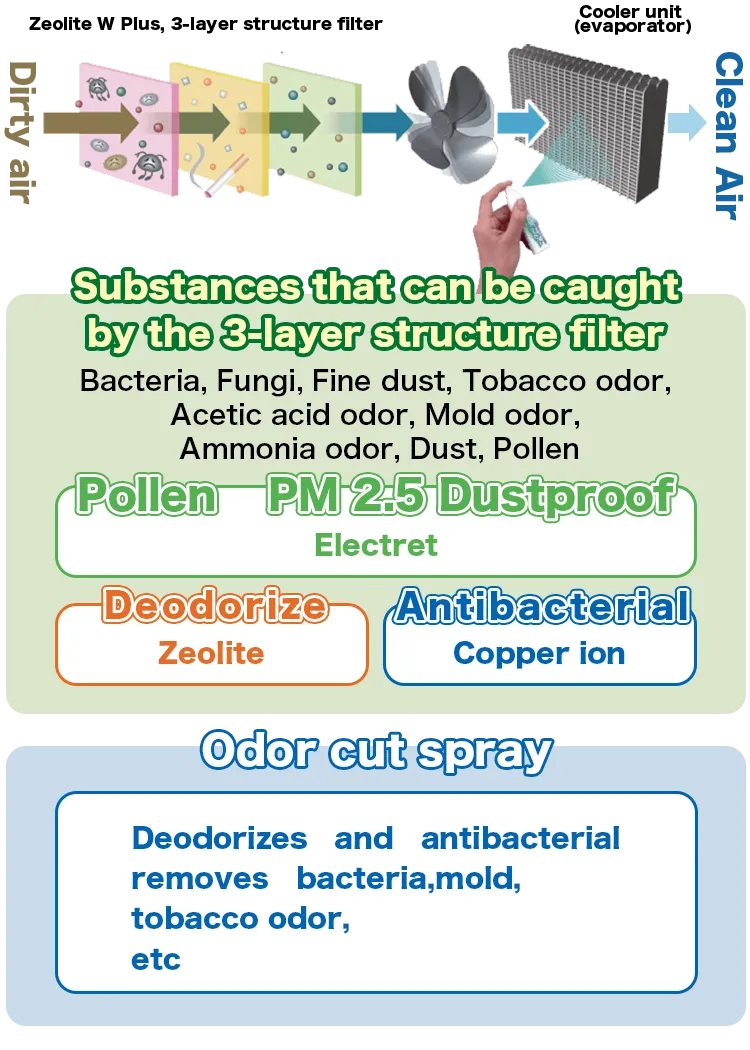

3 Adopts a filter media arrangement that maximizes the characteristics of three types of filter media

By using a low-pressure-loss electret nonwoven fabric,

we have made it possible to use the electret nonwoven fabric, which is conventionally used for the third layer, as the first layer.

As a result, we are now able to take full advantage of the function (viral inactivation) of the high-performance zeolite nonwoven fabric (Cellgaia) adopted in the second layer against fine particles such as viruses caught in the first layer.

we have made it possible to use the electret nonwoven fabric, which is conventionally used for the third layer, as the first layer.

As a result, we are now able to take full advantage of the function (viral inactivation) of the high-performance zeolite nonwoven fabric (Cellgaia) adopted in the second layer against fine particles such as viruses caught in the first layer.

1st

layer

Accurately captures fine particles such as viruses

Electrostatic non-woven fabric

Special technology creates electric fields inside and outside, demonstrating low pressure loss and high collection performance.

2nd

layer

Demonstrates deodorizing and antiviral functions

High-performance Zeolite non-woven fiber

This is a non-woven fabric which is made from high quality fiber that crystallizing Zeolite minerals within cellulose fibers using Rengo’s proprietary technology.

Copper is ion-exchanged with high-performance non-woven fabric to bring out Deodorizes and antibacterial.

What’s more it is quite safety material for human body.

Copper is ion-exchanged with high-performance non-woven fabric to bring out Deodorizes and antibacterial.

What’s more it is quite safety material for human body.

※Rengo・Cellgaia ™ is the product developed by Rengo Co., Ltd.

Zeolite W Plus・Zeolite Plus are the products equipped with Cellgaia .

What is Cellgaia?

Zeolite W Plus・Zeolite Plus are the products equipped with Cellgaia .

3rd

layer

Support for entire filter

Dust-proof non-woven fabric

It catches dust and pollen and maintains the strength of the entire filter.

It can be effective excellent antibacterial